|

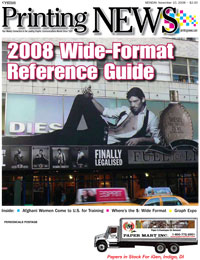

Nov. 10, 2008—The leaves are starting to change and the weather is getting nippy—that must mean it's time for Graph Expo, held again this year at McCormick Center in Chicago. Nov. 10, 2008—The leaves are starting to change and the weather is getting nippy—that must mean it's time for Graph Expo, held again this year at McCormick Center in Chicago.

Before the show, there was quite a bit of talk and worry that attendance would be down, and the show would take a hard hit from the economic troubles currently affecting the country. But while the overall traffic was down from previous years, those who did come were there to buy.

Every vendor I talked to at the show was pleased, as they were seeing qualified buyers come through, who were looking to invest in their business' future. The attendees were the ones who realize that a down economy is challenging, yes, but it also brings some great opportunities for those willing to take a few risks. Graph Expo drew out these folks this year, with questions and ideas for how they can position themselves for when things do swing up again, so they can rocket ahead of their competition.

One of the more interesting facts that crossed my path at the show was in a press conference, where a figure was cited that overall media and marketing buys in 2009 will be down around 12 percent in 2009. However, print is projected to be up around seven percent. Many companies threw huge amounts of money into new mediums over the past few years, and while they got thousands, if not millions, of clicks, they didn't see a corresponding rise in sales. So in a down economy, many are projecting a return to the tried-and-true—which means more print.

And when it comes to producing print, what new innovations did Graph have to offer to help shops do it faster, cheaper, and with higher quality? Here are a few of the products that caught our eye at the show.

Prepress Promises

Dalim Software featured the North American introduction of a number of products and features at the show, including an updated version of Mistral with Publishers Production Flatplan, geared to non-technical users for faster page approvals. While other page applications show flatplans of designed work, 3.0 shows PDF images of complete pages that have been produced through a production workflow. Another big draw at the booth was the North American introduction of Virtual Library. Just as the Publishers Production Flatpan improves the usability of Mistral, Virtual Library presents a realistic view of a magazine for approval. Drupa was the official launch of the system as an optional add-on to Printempo and Mistral. It was demonstrated officially for the first time in North America at Graph.

Press-sense featured iWay 5.0 and Press-sense Manager 2.0 at the show. The upgrade offers a completely new interface and multiple features, built upon an advanced infrastructure that fosters improved scalability, reduced cost of set up, and more flexibility. Beyond a new look and feel, iWay 5.0 also offers enhancements to enable the production of catalogs tailored to clients' interests, enhances variable-information production, and offers major advancements in job description parameters within the business workflow.

Presses Steal the Show

Xerox showcased the iGen4 in conjunction with a technology demonstration of the EPIC CTi-635 In-Line Coating System running aqueous-coating fluid. Aqueous coating is required for many applications and provides a fast-drying, water-based, clear coating to protect printed material from dirt, smudges, fingerprints and scratches. Aqueous coating is also used to enhance images and is available in a variety of finishes. This was the first official showing of the press in North America outside the company's demo center. It was officially launched at drupa in Germany this past spring. During the show, Xerox produced a variety of sample applications, including direct mail, short-run packaging, and pharmaceutical packaging.

Xanté introduced the Ilumina Digital Envelope Press+, which gives small to mid-sized shops the ability to print up to 60 full-color, #10 envelopes per minute; its 500 piece input capacity supports volume production demands such as those needed for transpromo applications. All Ilumina devices can print on window envelopes. Customers can also utilize the Ilumina-based system to produce full-color page mailings from its 500-sheet cassette, which has the ability to handle up to 12x18-inch paper, duplexed. It can produce full color output at up to 36 ppm and monochrome output up to 40 ppm.

"The Ilumina Digital Envelope Press+ gives small- and medium-sized printers the ability to increase volume output for on-demand mailings without sacrificing quality. Our customers are telling us we've hit the right chord with this product. We're happy to continue to bring solutions that meet the criteria for affordability, speed, reliability, and ease of use that help printers maximize their business opportunities," said Xanté CEO, Robert Ross.

The Production Printing Business Group (PPBG) of Ricoh Americas Corp. officially launched the Pro C900 at Graph, a digital color printer designed specifically for detailed production printing. The Pro C900 is capable of speeds up to 90 pages per minute for both black-and-white and color print jobs, even when printing on heavy stock paper (up to 110 lb cover/300gsm), and features a range of in-line finishing options. Pages are printed quickly for immediate distribution in the exit tray as complete documents.

"By providing businesses with faster turnaround times, higher throughput production, flexible finishing options, and low operating costs, the Ricoh Pro C900 is the ideal system for any business with advanced printing needs," said Carl Joachim, vice president of Marketing for PPBG, Ricoh Americas Corp.

"The versatile color printer is able to produce high-quality documents at a fast speed that empowers customers to take on large jobs they previously needed to outsource to third-party vendors," he added.

Inca Digital Printers announced the Onset S20, designed to deliver the high-volume production needs of specialist display print companies. The new printer, which will be available from global distributor Fujifilm Sericol, builds on the technology of the Inca Onset. This latest product introduction will allow Inca and Fujifilm Sericol to provide the industry with a choice of UV flatbed digital printers to suit all production requirements.

"The Onset is an ideal printer for customers with high productivity. However we recognize that most customers do not need to produce 6,458 sqft/hr of print. The Onset S20 is aimed at customers who like the features of the Onset, but who sell less output and want a lower price point. Inca can now offer customers machines to suit any budget, and throughput need, with the reliability and build quality associated with the Inca name," said Bill Baxter, MD of Inca Digital.

The Onset S20 prints edge to edge over a 123x63-inch area, on a moving bed on substrates nearly 2 inches thick. The vacuum table with accurate pin positioning allows users to print single and double sided on a variety of sheet sizes.

To provide users with an extra level of performance, a semi-automated material handling system is available as an option. While the standard color set of the Onset S20 is Fujifilm Sericol's Uvijet four color CMYK, Ultratone inks (lights, orange, violet) and white versions are also available. This—as well as a choice of satin, semi-gloss, and gloss finishes—delivers enormous versatility in the range of products that can be printed, e.g. display POS, exhibition graphics, backlit/frontlit displays, outdoor signage printing etc.

Postpress Wraps it All Up

The most interesting story in the postpress category wasn't around a product at all, although there were plenty of great options for shops to check out. Instead, it was the absence of a product.

When Autobond shipped the Mini laminator from its U.K. factory to Chicago for the show, the company had no reason to think that there would be a problem. However, U.S. customs had other ideas, and held the 40-foot container for an 'intensive inspection.' This delayed the machine by two weeks, leaving Autobond with no laminator to exhibit while the machine was being inspected in New York.

"The container held everything for the stand, from the laminator to the wall graphics," said managing director John Gilmore. "There wasn't even a sign saying Autobond. At the last minute, my son Oran and the other Autobond USA staff hired a 60-inch plasma screen in order to run videos of the equipment in operation, and they took lots of brochures. Beyond that they had nothing but their business cards!"

Despite the setback, by the second day Autobond had secured two orders, and a huge amount of interest. Autobond's recent decision to incorporate additional finishing processes within its laminators has proved to be extremely popular with printers and finishing houses, enabling them to offer services that might otherwise not be financially viable.

|